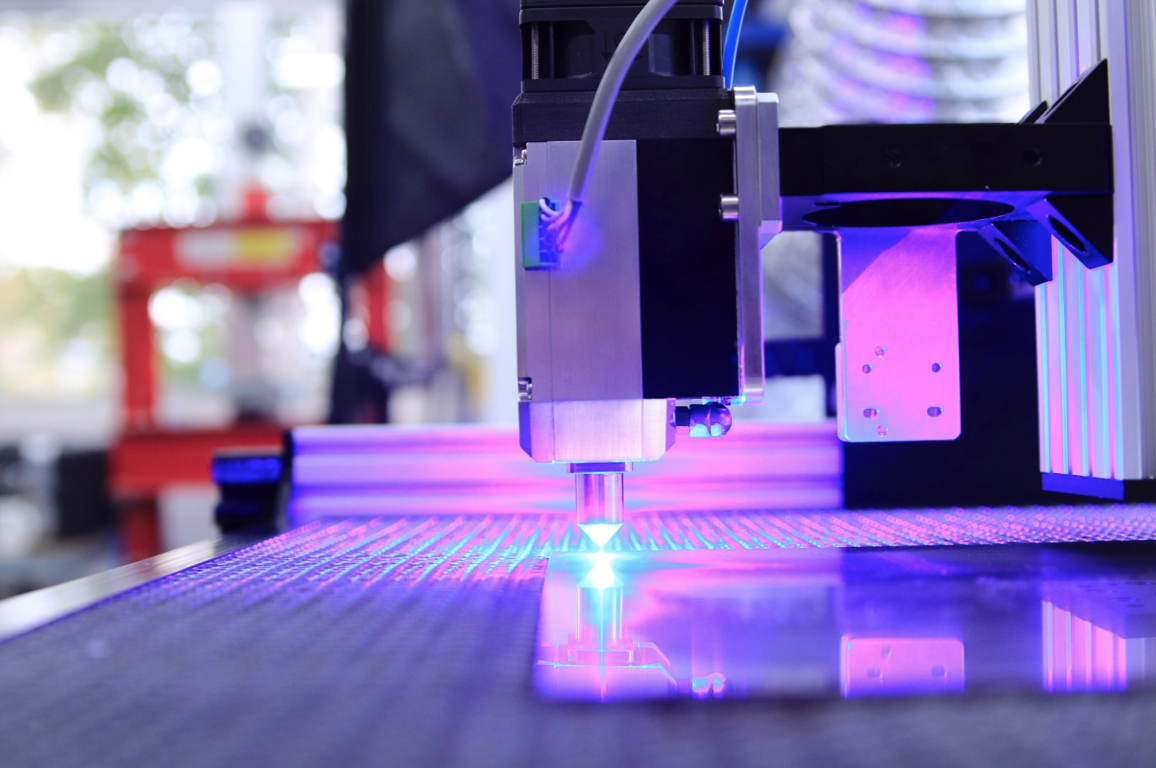

The most often used laser marking method for product trackability and identification is lasergraverenmachine. Making lasting markings on various materials entails utilizing a laser marking machine.

Before applying the technology to your project, this article will teach you everything you need to know about it.

Why Laser Engraving Is Used?

It entails utilizing a laser marking device—we’ll call it a laser engraving device—to melt particular regions on nearly any material. As a result, it creates permanent markings on the part or product that are more contrasty than the unmarked areas.

Using this method, logos, barcodes, serial numbers, and QR codes can be etched onto parts. The procedure creates a collection of extremely trustworthy processes in product decorating, traceability, and identification alongside laser etching, annealing, ablation, and other laser marking technologies.

A Synopsis of Laser Engraving’s History

The history of laser engraving cannot begin without including hand engraving. The act of manually engraving a part entail tracing a marking onto it with a sharp item (an engraving tool). For instance, circa 500,000 years ago, tools were engraved into stones. The oldest piece that has been painstakingly engraved so far is from roughly 500,000 years ago.

The development of technology throughout time led to improvements in manual engraving. Albert Einstein’s LASER 1916 invention and its subsequent improvement in the 1950s would serve as the foundation for the invention of laser engraving.

The first optical laser was made by Theodore Maimane. It would be assumed that Gordon Gould invented the first laser light.

With the introduction of the first laser machine by Western Electrics in 1965, lasers played a significant role in drilling. But it wasn’t until the introduction of CO2 lasers in 1967 that it was actually used for engraving. Further technological development has resulted in the creation of additional machine types used for engravings, including UV and MOPA laser markers.

What Is the Process of Laser Engraving?

Lasergraveren machine requires directing a laser beam of the appropriate power level at a part from a distance. This causes the substance to evaporate and leave a permanent impression on the pieces. It’s crucial to adjust the wattage since too much will burn the materials while too little will be ineffective.

Materials Used in the Process of Laser Engraving

Many different materials can be engraved with a laser. These are a handful that you might want to use for your project.

Plastics

Polymers like acrylic and POM are frequently used for laser engraving. However, the laser’s output power needs to be properly controlled and suited to the materials’ absorption spectrum and any other additives that may be present. CO2 and UV laser markers are more suitable with plastics.

Metals

The phrase “the heart of many industries” refers to the material that people laser engrave most frequently, which is metal. Stainless steel, gold, silver, iron, and aluminum are some examples of metals that work well with the procedure. The best marking devices for metals are fiber engraving machines.

Woods with laser engraving

Furthermore process-compatible are woods. The laser marker’s strength may be adjusted to allow you to etch wood without it catching on fire, though. You can use machines to engrave a variety of wood products, including plywood, MDF, and cardboard.

Finished Metals

The method can be used to vaporize coated metals, making it appropriate for these materials as well.

Difference Between engraving and laser marking

Laser marking is the process of applying sharp markings to various parts using laser-powered equipment. It includes a number of techniques, such as laser etching, engraving, ablation, and annealing.

The distinction between engraving and laser etching

Using a laser-powered device to melt and elevate the material’s surface is known as laser etching. Due of the high energy needed, unlike laser engraving, it can only be done using a fiber laser marker. Also, a considerable portion of the material will be removed (first thousandth of an inch or more) from the surface of the pieces by the laser engraving equipment in order to create the recognizable marking.

Conclusion

The accurate, long-lasting, and high-quality marks created by lasergraveren machine are created without any physical contact. As a result, it’s a crucial procedure for product identification and traceability in many businesses.